Product Categories

LQW screw centrifugal non clogging pump

- Detail

-

Product use:

This product is widely used in chemical, petroleum, pharmaceutical, mining, paper, cement, steel, power generation, coal processing industry and city sewage treatment plant to the drainage system, municipal engineering, construction sites, transportation and other industries with sewage dirt particles and fibers, also can be used for pumping clean water and corrosive medium.

Product condition:

1. motor rated voltage 380V, frequency 50Hz three-phase AC power supply.

2. conveying medium temperature is not more than 40 degrees centigrade, pH value is 4~10, density is less than 1.1 x 103kg/m3, solid phase volume is up to 20%.

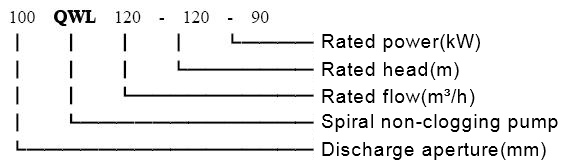

Product model specification:

Product performance and structural characteristics:

1, the Q-H curve is steep, the pump runs smoothly in a wide area, and the curve drift is small in the case of pumping complex media.

2, high efficiency, high efficiency, wide area, low operation and maintenance costs.

3, net absorption of low pressure, anti cavitation ability; stop water level low, greatly reduce the construction cost of the pool.

4. The power curve is smooth and without overload.

5, no blockage, no winding.

6, transportation can be transported intact soft, fish, fruits and vegetables and other fragile substances; in activated sludge reflow process of sewage treatment plant, the damage to zoogloea only for other forms of pump 1/10.

7. The medium with high solids content can be transported, for example, the slurry with solid content up to 20% can be transported.

8, using the international advanced Ansys-CFX software to optimize the design of hydraulic components, greatly improve the hydraulic performance of the pump, pump efficiency reached the international advanced level.

9. Using advanced international Ansys software to carry out scientific calculation and analysis of pump structure, improve the life of bearing and mechanical seal, reduce the vibration and noise of pump.

10, using a special cable outlet structure, eliminates burned due to man-made pulling, crushing, cable cable jacket aging and other accidental factors Water Leakage, leakage, short circuit and stator coil, effectively reduces the upper inlet failure probability.

11, built-in a number of early warning sensor, in the external control cabinet has phase missing, short-circuit, overcurrent and water level control protection, can realize the remote control and monitoring of the whole system.

12, the bearing is imported brand, reliable structure.

13, the product has applied double seal patent structure, greatly increased the reliability of the seal.

14, for high power submersible pump application of self circulation cooling system, using the impeller of the water pressure, so that the pump can ensure the motor running in the water cycle cooling.

15, the impeller of the pump adopts a large channel without clogging impeller, the blade line is designed according to the streamline, to ensure the large channel flow and high efficiency, smooth operation.

16. A replaceable wearable sleeve is installed between the impeller and the lower end of the volute to keep the pump running at the best efficiency.

Related Products

Welcome your message consultation

If you have any suggestions, please leave a message or send an email to us, and we will reply to you within one working day after receiving the message email.

中

中

EN

EN