Product Categories

QZ submersible axial pump

- Detail

-

Honesty Efficient Specialty

Hotline:0511-88889623

Product use:

In agriculture, it is used for irrigation and drainage; it is used for draining rainwater and mild sewage in municipal; in industry, it is used for process water, cooling water and raw water supply; for water conservancy, it is used for water transfer project. Suitable for transporting clear water or light sewage.

Product condition:

Motor rated voltage 380V, also can use 200 ~ 660V, 3KV, 6KV, 10KV and so on, rated frequency is 50Hz, working system is SI, insulation grade is F level.

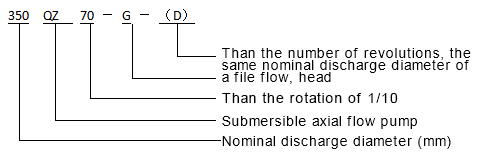

Product model specification:

Product features:

1. impellerThe impeller is converted by the most advanced hydraulic model, and the performance is excellent, stable and mature. Select smaller nD value, good cavitation performance, ensure smooth operation. The submersible pump model was adopted by the international cooperation and science and Technology Department of the Ministry of water resources in 2004, and the comprehensive technical indicators reached the leading level in China, and reached the advanced level of the international similar model.2. three heavy machinery seal and double seal chamber patent technologyIn the traditional submersible pump, there is only one oil chamber between the impeller and the motor room, and the double seal chamber adds an air buffer chamber between the oil chamber and the impeller, namely the double sealed chamber structure. Oil chamber is two independent machine seal, impeller and a mechanical seal, a total of three sets of mechanical seal. So when the water enters the air buffer chamber by the mechanical seal after the impeller when the water is deposited in the buffer chamber is low, water cannot enter the oil chamber, which realizes the complete isolation of water and the motor chamber, protect the dry environment in the motor chamber, protecting the bearing working environment in the oil chamber, greatly improve the reliability of the product.3. anti lift machine and anti reverse deviceWhen the unit starts, the reaction torque of the starting torque of the submersible pump motor often makes the unit rotate in the opposite direction. For the low pressure submersible pump, the anti reversal device can solve this problem. For larger submersible pumps, the normal starting often causes the unit to lift up due to the large force. The design of a fully sealed anti lift machine, anti reversal device, and the cable completely separated from the water, even after long-term use of rubber aging will not leak. There is also a leakage and fluid removal device to keep the drying in the sealing device.4. bearingsThe bearings are made of rolling bearings, capable of withstanding all axial and radial loads, and are completely separated from the medium conveyed by the pump. In the bearing structure design of large submersible pump, adopt short cylindrical roller bearing does not bear radial force, axial force of submersible pump to withstand the thrust bearing, ball bearing to prevent axial movement of the program, and is provided with a bearing temperature measuring element to ensure the stable and safe operation of electric pump.5. motorHigh squirrel cage induction motor, especially for submersible pump design and manufacture, conforms to GB755 standard. The power rating of a motor with IEC standards, protection grade IP68, rated voltage can be based on 380V, 660V, 3KV, 6KV, 10KV, the rated frequency is 50Hz, working for SI, insulation class is F and VPI by vacuum pressure impregnation process has good mechanical properties and reliable waterproof performance.6. coolingSubmersible pump submerged into the water, the motor shell directly heat to the surrounding media, the heat is taken away by the surrounding water. High power high voltage electric pump motor adopts internal air duct heat dissipation technology, which makes the three-phase winding low temperature rise and uniform temperature field distribution.7. Monitoring deviceSubmersible pump is equipped with multi-channel protection device, which can lead the lead to the electric control box. The protection device includes overload, phase missing, leakage, over temperature, temperature, immersion protection and so on (depending on the structure of the pump is different).

Related Products

Welcome your message consultation

If you have any suggestions, please leave a message or send an email to us, and we will reply to you within one working day after receiving the message email.

中

中

EN

EN